Sodium Hydroxide Usage Calculator

How Much Sodium Hydroxide Do You Use Daily?

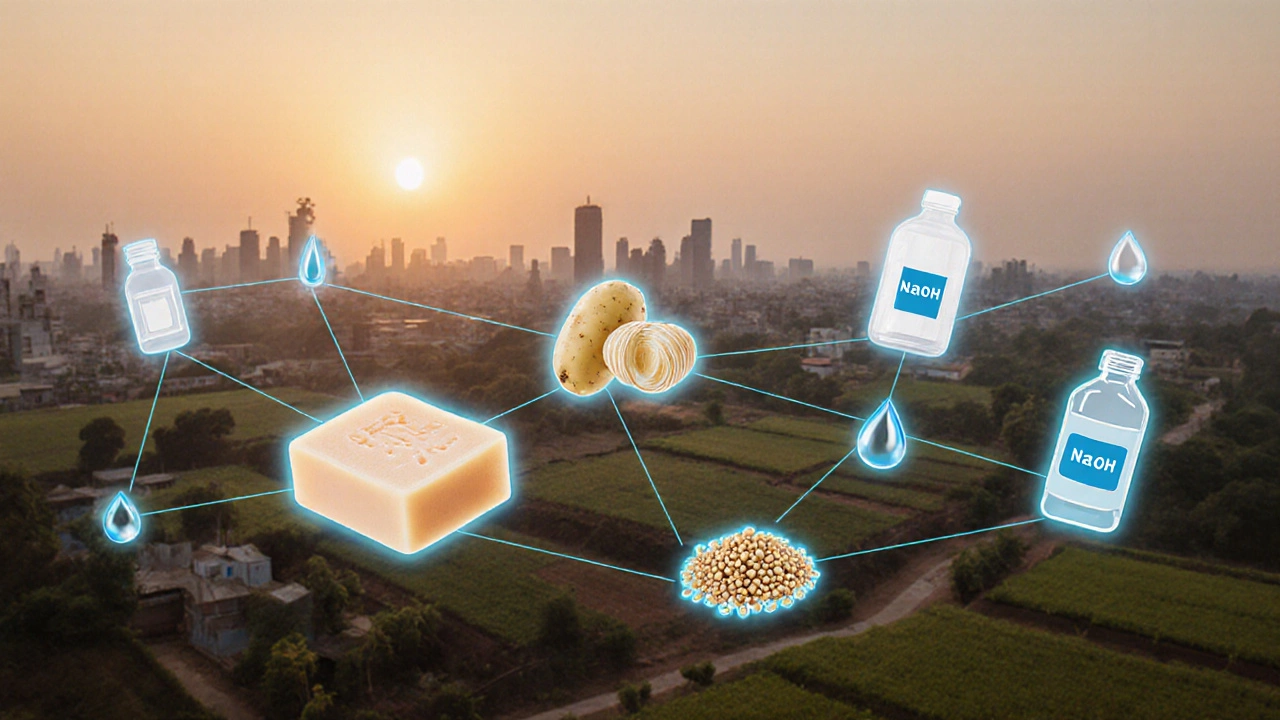

Sodium hydroxide (caustic soda) is used in everything from soap to food processing. Estimate your daily usage based on common products.

What This Means

National Context

India's annual consumption: 4.2 million metric tons

Your daily usage:

(This is of India's daily usage)

India uses over 100 million metric tons of chemicals every year. But one chemical stands out-not because it’s the most expensive, not because it’s the flashiest, but because it’s in everything. From the soap you wash with to the food you eat, from the clothes you wear to the medicine you take-this chemical is the silent backbone of Indian industry. That chemical is sodium hydroxide, also known as caustic soda.

Why Sodium Hydroxide Rules Indian Industry

Sodium hydroxide (NaOH) isn’t just a chemical-it’s a workhorse. In 2024, India consumed more than 4.2 million metric tons of it, according to data from the Indian Chemical Council. That’s more than double the usage of any other industrial chemical in the country. You won’t find it on supermarket shelves, but you’ll find it in almost every product you buy.

It’s used to make soap and detergents, which is why India’s $20 billion household cleaning market runs on it. It’s used to process cotton in textile mills, turning raw fibers into the fabric that makes up 70% of India’s apparel exports. It’s used to refine crude oil in refineries across Gujarat and Maharashtra. It’s even used in water treatment plants to clean drinking water for over 100 million urban households.

And then there’s the food industry. Sodium hydroxide is used to peel fruits and vegetables on an industrial scale. Think of the potatoes in your chips or the olives in your salad dressing-they’ve likely been treated with it. Even traditional Indian foods like pretzel-like laddoos or certain types of papad use it in small amounts for texture and shelf life.

How It Powers Agriculture and Fertilizers

India is the third-largest fertilizer producer in the world, and sodium hydroxide plays a hidden role here too. While urea and ammonium phosphate get all the attention, NaOH is critical in the production of ammonium nitrate and ammonium sulfate-two key nitrogen sources for crops. Farmers in Punjab, Haryana, and Uttar Pradesh rely on these fertilizers to grow wheat and rice. Without sodium hydroxide, the cost of fertilizer would jump by 15-20%, directly affecting food prices.

It’s also used to adjust soil pH in large-scale farming. In regions where soil has become too acidic from years of chemical use, sodium hydroxide helps neutralize it. The government’s Soil Health Card Scheme, which covers over 140 million farmers, recommends pH correction using alkaline agents like NaOH in specific zones.

The Chemical Manufacturing Boom in India

India isn’t just using sodium hydroxide-it’s making it. The country now produces over 5 million metric tons annually, with a 7% annual growth rate since 2020. Major plants are clustered in Gujarat, Tamil Nadu, and Maharashtra. Companies like Tata Chemicals, Reliance Industries, and UPL are the top three producers, accounting for nearly 60% of domestic output.

What’s driving this growth? Export demand. Countries in Southeast Asia, Africa, and the Middle East import Indian-made sodium hydroxide because it’s cheaper and more reliable than sourcing from China or the U.S. In 2024, India exported over 1.1 million metric tons of NaOH-up 22% from the year before. That’s more than any other chemical India exports by volume.

Domestic demand is rising too. With India’s textile industry expanding and its pharmaceutical sector growing at 12% per year, the need for NaOH keeps climbing. Every new detergent factory, every new vaccine production line, every new textile mill-each one adds to the demand.

Other Major Chemicals in India-But None Like NaOH

Sure, other chemicals are big in India. Sulfuric acid is used in fertilizer production and battery manufacturing. Ammonia is critical for urea. Hydrochloric acid is used in steel pickling. But none of them touch sodium hydroxide in versatility.

Take sulfuric acid, for example. It’s used mostly in one industry: fertilizer. That’s it. Sodium hydroxide? It’s used in textiles, food, pharmaceuticals, water treatment, soap, paper, aluminum production, and even in making biodiesel. It’s the only chemical that shows up in all five of India’s top manufacturing sectors: chemicals, textiles, food, pharma, and agrochemicals.

And here’s the kicker: sodium hydroxide is cheaper than most alternatives. A ton of NaOH costs around $300-$350 in India, while equivalent alkaline alternatives like potassium hydroxide cost over $800. For industries running on thin margins, that price difference makes NaOH the only real choice.

Environmental and Safety Concerns

With great use comes great responsibility. Sodium hydroxide is highly corrosive. It can cause severe burns. If spilled into rivers, it can kill aquatic life. In 2023, a leak from a chemical plant in Gujarat led to the death of over 10,000 fish in the Sabarmati River. That incident triggered new rules under the Hazardous and Other Wastes (Management) Rules, 2016.

Today, factories that produce or use NaOH must have closed-loop water systems, emergency neutralization tanks, and real-time pH monitors. The Central Pollution Control Board now requires quarterly audits for all large-scale users. Many plants have switched to solid pellet form instead of liquid to reduce spill risks.

Workers handling NaOH wear full protective gear-gloves, face shields, chemical-resistant suits. Training is mandatory. In Tamil Nadu, where over 40% of India’s NaOH production happens, the state labor department runs certification programs for chemical handlers.

What’s Next for Sodium Hydroxide in India?

The future of sodium hydroxide in India is tied to two trends: green manufacturing and circular economy.

Companies are now producing NaOH using renewable energy. Tata Chemicals launched India’s first solar-powered caustic soda plant in 2023. It cuts carbon emissions by 35% compared to coal-powered plants. Other firms are following. By 2027, over 40% of India’s NaOH is expected to come from low-carbon sources.

Recycling is also gaining ground. Textile mills are now recovering NaOH from wastewater and reusing it. In Surat, a pilot project recovers 85% of the NaOH used in dyeing, reducing fresh chemical purchases by 70%. Similar systems are being rolled out in Pune and Coimbatore.

And then there’s innovation. Researchers at IIT Bombay are developing a new form of solid NaOH that dissolves only at specific temperatures-making it safer to transport and use in food processing. If it scales, it could replace liquid NaOH in half the applications by 2030.

Final Thought: The Invisible Giant

You don’t see sodium hydroxide. You don’t hear about it in the news. But if it vanished tomorrow, India’s economy would grind to a halt. Soap wouldn’t lather. Clothes wouldn’t be dyed. Food wouldn’t be cleaned. Water wouldn’t be safe. Medicine wouldn’t be made. Fertilizers wouldn’t work.

It’s not glamorous. It’s not trendy. But sodium hydroxide is the most highly used chemical in India-not because it’s special, but because it’s essential. And in a country where 90% of manufacturing depends on affordable, reliable inputs, that’s the highest honor a chemical can earn.

Is sodium hydroxide safe for home use?

Sodium hydroxide is not safe for casual home use. It’s a strong alkali that can cause severe chemical burns on skin and eyes. While some drain cleaners contain small amounts, they’re highly concentrated and dangerous if misused. Always keep it out of reach of children and never mix it with other chemicals like bleach or vinegar. If you need to clean drains, use safer alternatives like baking soda and vinegar.

Which Indian companies produce sodium hydroxide?

The top three producers are Tata Chemicals, Reliance Industries, and UPL. Tata Chemicals operates major plants in Mumbai and Mithapur, while Reliance has large-scale facilities in Jamnagar. UPL, based in Pune, is the largest exporter. Smaller players like Gujarat Alkalies and Chennai Chemicals also contribute to domestic supply.

Why is sodium hydroxide cheaper in India than in other countries?

India produces sodium hydroxide using low-cost coal-powered electrolysis and has a large domestic market, which drives economies of scale. Labor and regulatory costs are lower than in the U.S. or EU. Plus, India doesn’t impose heavy import duties on salt (the raw material), keeping input costs down. This makes Indian NaOH 20-30% cheaper than imported alternatives.

Can sodium hydroxide be replaced in industrial applications?

In most cases, no-not without major cost increases. Alternatives like potassium hydroxide or calcium hydroxide are either too expensive or less effective. Some industries are experimenting with enzymatic cleaning agents in textiles, but they’re still 3-4 times more costly. For now, sodium hydroxide remains the only practical option for large-scale use in soap, food, and pharma.

How does sodium hydroxide affect the environment?

If released untreated into waterways, sodium hydroxide raises pH levels sharply, killing fish and aquatic plants. It can also damage soil structure if overused in agriculture. However, modern Indian factories now treat wastewater before discharge, and regulations require neutralization before disposal. The environmental impact is now tightly controlled, but historical pollution in some river basins still lingers.