Pasteurization Safety Calculator

How to Use This Tool

Enter your pasteurization temperature and time to check if it meets food safety standards. The tool follows FDA and EU regulations for safe food processing.

Critical thresholds: 72°C for 15 seconds (milk), 85°C for 30 seconds (soups), 95°C for 15 seconds (juices)

When you walk into a modern food processing plant, you might see robots filling jars, conveyor belts moving products, and screens showing temperature readings. But what’s really running all of this? It’s not the people. It’s not the machines alone. It’s something quiet, hidden, and absolutely essential: ROM.

ROM stands for Read-Only Memory. If you’ve ever heard of computers having RAM, you might think ROM is just the older, slower cousin. But in food processing, ROM isn’t just memory-it’s the brain’s hardwired rulebook. It doesn’t change. It doesn’t crash. And if it works, your peanut butter jar gets sealed right every time, 24 hours a day, seven days a week.

What Exactly Is ROM?

Think of ROM like the recipe book in a bakery that never gets rewritten. Every morning, the bakers open the same book, follow the same steps, and bake the same bread. No one says, "Let’s try adding chocolate chips today." That’s because the recipe is fixed. ROM works the same way.

In computers, ROM stores instructions that the machine needs to start up and run basic functions. In food processing units, those instructions control things like:

- When a conveyor belt turns on or off

- How long a pasteurizer heats milk

- What temperature triggers a shutdown if something goes wrong

- How much sauce gets dispensed into each container

Unlike RAM (Random Access Memory), which forgets everything when the power goes out, ROM keeps its data forever-even without electricity. That’s why it’s perfect for food plants. If a power surge hits at 3 a.m., the system doesn’t need to relearn how to pasteurize. It just restarts, and the rules are still there.

Why ROM Matters in Food Safety

Food safety isn’t about guesswork. It’s about consistency. The FDA, Australia’s TGA, and the EU all require strict controls on temperature, timing, and contamination levels. If a machine gets a new software update and starts overcooking chicken, someone could get sick.

That’s why most food processing machines use ROM for their core operations. The settings that keep food safe are locked in. No one can accidentally change them. No hacker can rewrite them. No employee can update the system during a rush and mess everything up.

For example, in a dairy plant in New South Wales, the pasteurization process runs on ROM. It’s set to heat milk to 72°C for exactly 15 seconds. That’s not a suggestion. That’s the law. If the machine tried to adjust that on its own, it would be dangerous. But with ROM? It’s impossible to change unless a technician physically rewrites the chip-which takes hours, requires special tools, and leaves a log.

ROM vs RAM: What’s the Difference?

It’s easy to mix up ROM and RAM. Here’s how to tell them apart:

| Feature | ROM | RAM |

|---|---|---|

| Stays powered off? | Yes | No |

| Can it be changed? | Only by technician | Always, instantly |

| Used for? | Core safety rules | Temporary tasks (like logging) |

| Speed | Slower | Faster |

| Example in plant | Heating cycle for canned soup | Tracking how many jars were filled today |

RAM handles the day-to-day tracking: how many units were produced, which machine had a hiccup, what time the shift started. But ROM? ROM makes sure the machine doesn’t accidentally turn into a hazard.

Where You’ll Find ROM in a Food Plant

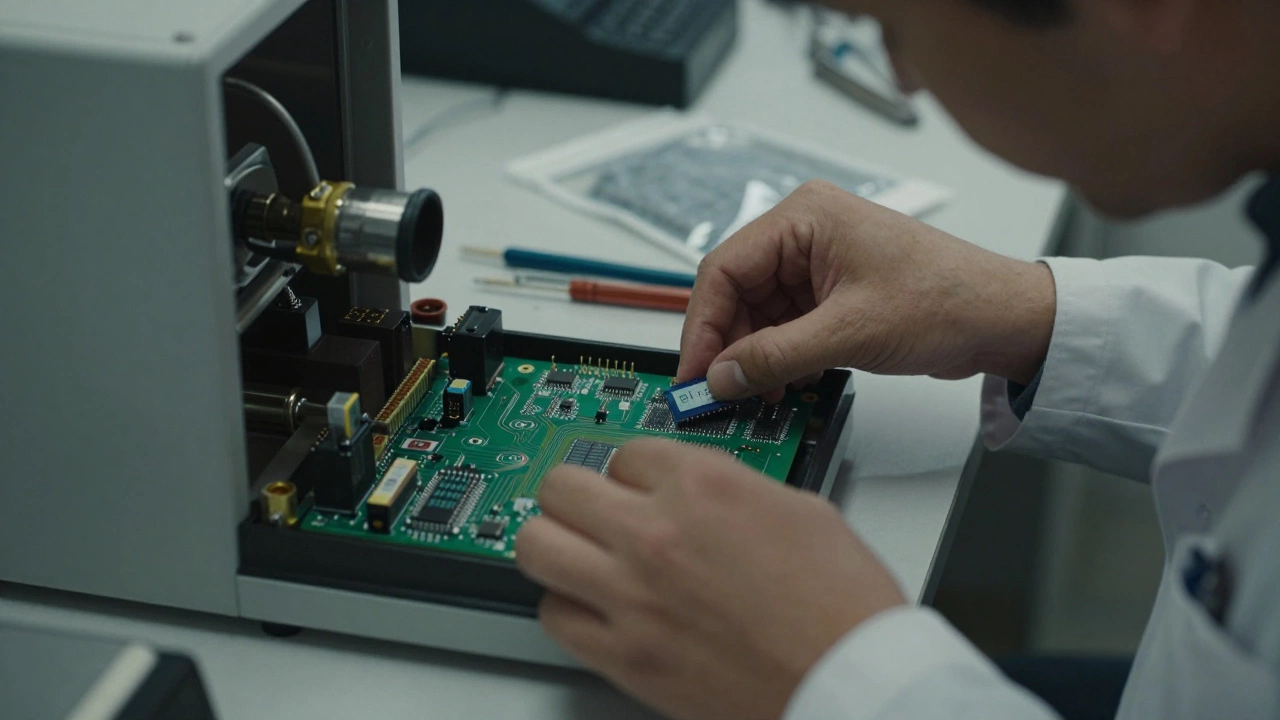

You won’t see ROM sitting on a shelf. It’s inside small chips, usually labeled with numbers like "27C512" or "EEPROM". But here’s where it lives:

- Filler machines: ROM controls how much product goes into each bottle or pouch. Too little? You get fined. Too much? You lose money.

- Sealing units: The heat and pressure needed to seal a jar? Locked in ROM. Change it, and you risk leaks or contamination.

- Temperature controllers: In meat processing, a 2°C difference can mean the difference between safe and spoiled. ROM keeps it exact.

- Quality sensors: If a camera spots a broken label, ROM tells the machine to reject it-no exceptions.

Even in automated packaging lines, ROM is the silent guard. It doesn’t make decisions. It doesn’t learn. It just follows the rules. And that’s exactly what you want when you’re dealing with food.

What Happens When ROM Fails?

ROM doesn’t break often. But when it does, it’s a big deal. Unlike software that can be reinstalled, ROM chips are physical. If one fails, the machine won’t start. It won’t run. It just sits there.

At a juice bottling plant in Melbourne, a faulty ROM chip caused a line to shut down for 18 hours. The machine kept trying to seal bottles at 80°C instead of 75°C. That didn’t kill the product-but it warped the caps, and the entire batch had to be thrown out. The fix? A technician swapped the chip. Took two hours. Cost $12,000 in lost product.

That’s why most plants keep spare ROM chips on hand. Not every model, but the critical ones. They’re stored in anti-static bags, labeled clearly, and tested monthly. It’s not fancy. But it’s necessary.

Is ROM Still Used Today?

You might think with AI and cloud systems, ROM is outdated. But in food processing? It’s more important than ever.

Cloud-connected machines are great for monitoring. But if the internet goes down, and the machine tries to update its settings from a server? That’s risky. What if the update has a bug? What if it’s hacked?

That’s why modern food plants use a hybrid approach:

- ROM: Handles safety-critical functions

- RAM + Cloud: Handles data logging, reporting, scheduling

So yes, ROM is still here. And it’s not going anywhere. It’s the reason your canned soup doesn’t have a metal taste. It’s why your baby food is sterile. It’s the invisible layer that keeps everything safe.

What’s Next for ROM in Food Processing?

ROM isn’t getting smarter. It’s getting better at being simple. Newer versions use flash memory, which lets technicians update the code safely-without replacing the chip. But even then, updates require:

- Two-person approval

- Offline mode

- Backup copies

- Full audit trail

The goal isn’t to make ROM flexible. It’s to make sure no one ever has to ask, "Why did the machine do that?"

Food processing doesn’t need innovation in ROM. It needs reliability. And that’s exactly what ROM delivers.