Environmental Impact of Manufacturing

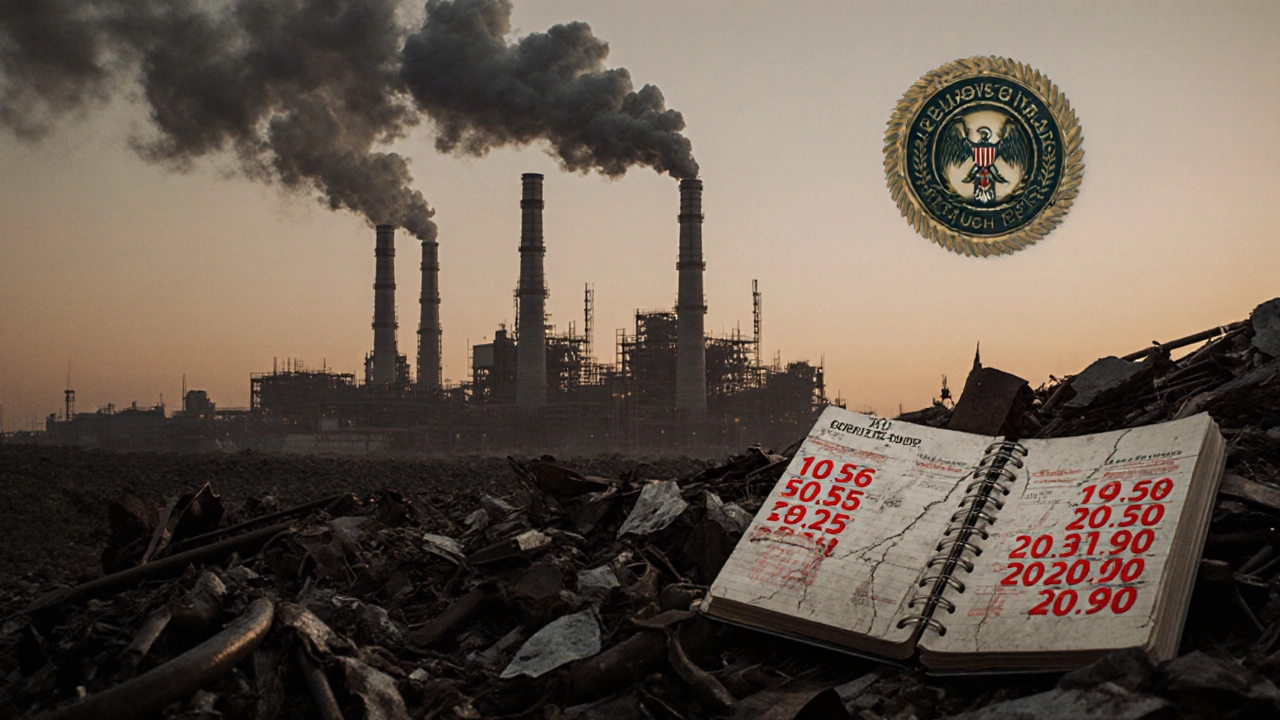

When we talk about the environmental impact of manufacturing, the unintended harm caused by industrial production on natural systems. Also known as industrial pollution, it includes air emissions, toxic waste, water contamination, and energy waste that come from making everything from steel to smartphones. This isn’t just a global problem—it’s happening right here in India, where factories are growing faster than regulations can keep up.

The manufacturing pollution, the release of harmful substances from industrial processes shows up in multiple ways. Factories burn coal and diesel to power machines, spewing out carbon dioxide and soot. In places like Tamil Nadu and Gujarat, textile mills dump dye-filled water into rivers. Chemical plants in Uttar Pradesh and Maharashtra leak sodium hydroxide and other toxins into soil. Even small-scale metal workshops, like those making custom planters or tools, contribute through smoke and scrap waste. These aren’t abstract risks—they’re real problems affecting drinking water, farm yields, and air quality in nearby towns.

But there’s a shift happening. Some Indian manufacturers are cutting waste by reusing water, switching to solar power, or recycling metal scraps. The same factories that produce textiles for global brands are now adopting cleaner dyeing methods. Electronics makers are starting to recover precious metals from old circuit boards. And with government push behind sustainable manufacturing, production methods that reduce resource use and environmental harm, more businesses are realizing that being green isn’t just ethical—it’s profitable. The green manufacturing, industrial practices designed to minimize ecological damage while maintaining output movement is growing, not because of pressure, but because smarter, cleaner operations save money in the long run.

What you’ll find below are real stories from India’s manufacturing scene—some showing the damage, others showing the fix. You’ll see how a single chemical like sodium hydroxide powers entire industries but also poisons rivers. You’ll learn why Chinese steel is cheaper, and how looser environmental rules play a part. You’ll read about textile hubs turning waste into profit, and how small workshops are cutting emissions without big budgets. This isn’t theory. It’s what’s happening on the ground—and what you need to know to understand where Indian manufacturing is headed.

Explore the main drawbacks of manufacturing, from environmental impact to high capital costs, supply‑chain risks, labor issues, and compliance burdens, plus tips to mitigate them.