Small Scale Manufacturing Viability Calculator

- Employees: Under 50 full-time workers

- Annual Turnover: Under $5 million USD

- Capital Investment: Under $500,000

- Local/Regional Market Focus

- Manual or Semi-Automated Production

Enter your business details to see if you qualify as small scale manufacturing

When people hear small scale manufacturing, they often picture a modest workshop buzzing with activity, producing goods for a local market. In reality, it’s a distinct business model that balances limited resources with flexibility, allowing entrepreneurs to carve out niche markets without the massive overhead of a factory floor. Small Scale Manufacturing is the production of goods using limited capital, labor, and equipment, typically serving regional or specialized markets rather than mass‑consumer channels. Understanding this model helps readers decide if it fits their business goals, especially when paired with related concepts like Microenterprise and Lean Manufacturing practices.

What Qualifies as Small Scale Manufacturing?

There’s no universal cutoff, but most governments and industry bodies use a combination of the following metrics:

- Employee count: typically fewer than 50 full‑time workers.

- Annual turnover: often under $5 million USD, though thresholds differ by country.

- Production capacity: measured in units per year or total output volume, usually well below the output of large factories.

- Capital investment: limited to a few hundred thousand dollars for equipment and facilities.

These criteria overlap with the definition of a Microenterprise, which is a business with very low revenue and staff, but the key difference lies in the focus on producing tangible goods rather than services.

Key Characteristics

- High flexibility - you can quickly pivot product designs or switch materials.

- Close customer relationships - often selling directly to end users or local retailers.

- Manual or semi‑automated processes - machinery is usually compact and easy to maintain.

- Limited supply‑chain depth - many inputs are sourced locally.

- Emphasis on quality over quantity - niche markets often demand premium craftsmanship.

Benefits and Challenges

Benefits

Running a small scale operation offers several upside points:

- Lower entry barriers: Minimal upfront capital makes it accessible for first‑time entrepreneurs.

- Rapid decision‑making: With fewer layers of management, you can implement changes within days.

- Community impact: Local hiring and sourcing boost the regional economy.

- Customization: Ability to tailor products to specific customer feedback.

Challenges

However, small scale manufacturers also face hurdles that larger players can absorb more easily:

- Higher per‑unit costs due to limited economies of scale.

- Financing constraints - banks often view them as riskier borrowers.

- Regulatory compliance - safety and environmental standards still apply.

- Talent retention - skilled workers may be attracted to bigger firms.

Typical Industries and Real‑World Examples

Several sectors thrive under the small scale model:

- Textile Manufacturing: Artisan workshops producing organic cotton clothing for boutique stores.

- Food Processing: Small dairies crafting specialty cheese sold at farmers’ markets.

- Furniture Manufacturing: Hand‑crafted wooden tables sourced from local timber.

- Electronics Manufacturing: Low‑volume assembly of custom IoT devices for niche applications.

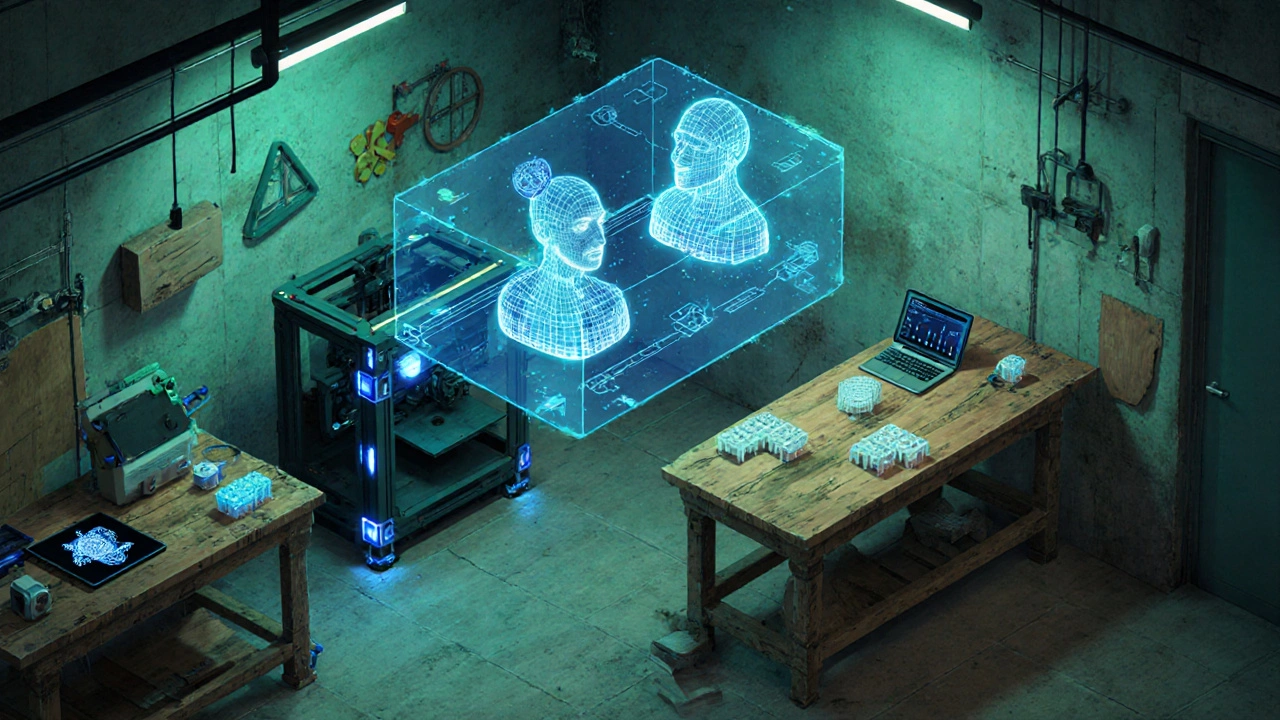

- Plastic Manufacturing: 3D‑printing services offering rapid prototyping for start‑ups.

These examples illustrate how Artisan Workshop models blend creativity with modest production runs.

How to Start a Small Scale Manufacturing Unit

- Identify a niche market: Conduct informal surveys or use platforms like Instagram to gauge demand.

- Develop a prototype: Use affordable tools-CNC routers, laser cutters, or even basic hand tools-to create a sample.

- Calculate production capacity: Estimate the maximum units you can produce per month based on available labor and equipment. This ties directly into your Production Capacity metric.

- Secure financing: Explore Government Scheme options such as the MSME Development Fund, low‑interest loans, or crowd‑funding.

- Set up the workspace: Choose a location with easy access to raw‑material suppliers and your target Local Market.

- Establish a supply chain: Build relationships with reliable vendors for components, packaging, and logistics.

- Implement lean practices: Adopt Lean Manufacturing techniques to minimize waste and improve flow.

- Launch a pilot run: Produce a limited batch, gather feedback, and iterate before scaling.

Government Schemes and Financing Options

Many countries recognize the importance of the small scale sector and offer tailored support. In India, for instance, the Credit Linked Subsidy Scheme (CLSS) provides interest subsidies for equipment purchases. The U.S. Small Business Administration (SBA) runs the Microloan Program, offering loans up to $50,000 with favorable terms. Europe’s European Structural and Investment Funds (ESIF) allocate money for regional manufacturing clusters.

When evaluating options, consider the following criteria:

- Eligibility - Does the scheme target MSME categories?

- Funding amount - Is it sufficient for your capital investment needs?

- Repayment schedule - Does it align with projected cash flow?

- Additional support - Training, technology adoption assistance, or market linkages?

Small Scale vs. Large Scale Manufacturing

| Aspect | Small Scale | Large Scale |

|---|---|---|

| Typical Employees | 1-50 | 500+ |

| Capital Investment | $50K-$500K | >$10M+ |

| Production Volume | Hundreds to low‑thousands per year | Millions per year |

| Flexibility | High - quick design changes | Low - long retooling cycles |

| Supply‑Chain Depth | Short - local suppliers | Complex - global networks |

| Regulatory Burden | Basic safety/environmental compliance | Extensive certifications (ISO, OSHA, etc.) |

This side‑by‑side view helps entrepreneurs decide whether to stay small and agile or invest in scaling up.

Future Trends Shaping Small Scale Manufacturing

Even modest operations aren’t immune to tech disruptions. Here are three trends to watch:

- Digital Twins: Low‑cost simulation software lets a workshop model its production line before buying equipment.

- Industry 4.0 Add‑ons: Plug‑and‑play IoT sensors monitor machine health, reducing downtime without massive IT projects.

- Sustainable Materials: Consumers increasingly demand eco‑friendly products, prompting small manufacturers to adopt biodegradable plastics or reclaimed wood.

By embracing these tools, small scale producers can punch above their weight and stay competitive against larger rivals.

Frequently Asked Questions

What defines a small scale manufacturing business?

It’s a production setup that operates with limited capital, a small workforce (usually under 50), and modest output volumes, often focusing on niche or local markets.

Can a small scale manufacturer qualify for government subsidies?

Yes. Many countries run schemes specifically for MSME firms, offering low‑interest loans, equipment grants, or training programs.

What is the typical initial investment needed?

It varies by industry, but most small workshops start with $50,000-$200,000 for machinery, lease space, and working capital.

How does lean manufacturing apply to small scale operations?

Lean principles-like minimizing waste, continuous improvement, and just‑in‑time inventory-fit naturally because small units already have short supply chains and can adapt quickly.

Is it possible to scale up later?

Absolutely. Many businesses begin small to validate the market, then reinvest profits to buy larger equipment, hire more staff, and expand distribution.