India's auto factories are massive, but one place tops them all and shapes how Indians drive. The Maruti Suzuki plant in Manesar, Haryana, isn't just big—it's a city in itself. This plant cranks out more cars in a year than some countries do, with models parked everywhere: from the smallest city runabout to family hatchbacks you see lined up at every supermarket.

Here’s the kicker—this single location has rolled out over a million cars annually since 2016, and the numbers keep climbing. You'd think such a pace means endless chaos, but the place is so organized that you'd almost expect to hear robots gently humming lullabies at night. It's also a job machine, giving work to thousands and acting like a magnet for engineers, designers, and techies fresh out of college.

Whether you’re a gearhead, a parent looking for a reliable family car (like I did when Sienna outgrew her toddler seat), or just nosy about what powers India’s car market, this plant has a bigger effect on your daily routine than you might guess.

- The Giant: Identifying India's Largest Car Plant

- Key Stats and Surprising Numbers

- How the Plant Impacts Everyday Life

- Behind the Scenes: Robots, Humans, and Innovations

- Tips for Visitors and Industry Watchers

The Giant: Identifying India's Largest Car Plant

When it comes to sheer size and output, nothing comes close to the largest car plant India has ever seen—the Maruti Suzuki facility in Manesar, Haryana. If you're picturing a regular factory, think again. The Manesar campus covers over 600 acres, which is about the size of 450 football fields stacked together. This isn’t just Maruti Suzuki’s biggest plant; it’s the largest single-site car manufacturing facility in the country.

This monster of a plant got rolling in 2007 and quickly took the top spot. Unlike older industrial complexes, it's high-tech from end to end. To give you an idea of what goes on inside, this facility alone can produce roughly 900,000 cars a year. Put differently, nearly one out of every three cars sold in India comes rolling out from behind its gates.

Here's a peek at the main stats that blow away most folks:

| Plant Name | Location | Total Area (acres) | Annual Capacity | Models Produced | Year Started |

|---|---|---|---|---|---|

| Maruti Suzuki Manesar | Manesar, Haryana | 600+ | 900,000 cars | Swift, Dzire, Ciaz, Baleno, others | 2007 |

That number is so big that on a good day, there’s a new car coming off the line every minute. They build favorites like the Swift, Dzire, Ciaz, and Baleno—all household names for anyone with an eye on Indian roads.

Why does this matter for you? A factory of this size keeps prices down, puts more models within reach, and makes spare parts super easy to get, even in tiny towns. It’s the backbone of India’s affordable car boom, whether you’re thinking of buying new or picking up a used ride.

Key Stats and Surprising Numbers

Alright, so let’s get down to numbers. The largest car plant in India is the Maruti Suzuki facility in Manesar, and it churns out jaw-dropping figures. At peak production, this plant can make over 5,500 cars a day. Just to put that in perspective: that’s a car rolling out roughly every 16 seconds when things are running at full speed.

This factory complex spreads across around 600 acres—about the size of 340 football fields linked together. It’s not just the size, but the muscle too. The Manesar facility, including its sister plants in Gurgaon, has crossed the production of 27 million vehicles as of 2024. So nearly every third car you spot on Indian roads probably passed through these gates.

The jobs? Manesar alone keeps over 15,000 folks employed on the factory floor, not counting thousands more in supplier and logistics roles. The ripple effect is huge: one industry report from The Economic Times mentions that for every direct job at Maruti Suzuki, up to seven more are supported outside the factory.

"Manesar has become the nerve center of India’s car manufacturing story," says R.C. Bhargava, Chairman of Maruti Suzuki, in a 2023 CNBC interview. "It’s not just about big numbers, but about setting new benchmarks for quality and efficiency in the whole region."

Thinking about exports? Manesar isn’t just building local favorites. In 2023 alone, they shipped over 2.8 lakh cars to more than 100 countries, making it one of the top exporters among Indian car plants. So, if you’re traveling abroad and spot a compact Maruti, there’s a good chance it started its journey here.

To sum it up, when you see the scale—both in space and impact—it’s no wonder this plant holds the top spot.

How the Plant Impacts Everyday Life

If you’ve ever driven a hatchback in India, there’s a good chance it rolled out of the massive Maruti Suzuki Manesar plant. This place doesn’t just pump out cars—it helps fuel family road trips, daily commutes, jobs, and even dreams of going on that first Goa vacation.

The most obvious impact is work. The plant employs over 17,000 people directly, but it doesn’t stop there. Local suppliers, parts companies, vendors of canteen food, security staff—tens of thousands of folks depend on this one giant hub for a steady paycheck. For every single job inside the plant, roughly five more are created outside, from tire makers to neighbourhood tea stalls serving quick chais during shift breaks.

Money from the plant trickles out in other ways. Local schools, hospitals, and small businesses see more customers since the plant keeps people in the area, working and spending. That means if you’re running a small stationery shop near Manesar, some of your best clients likely work for or with the plant.

The factory is also a training ground for new technologies. Stuff like advanced robotics, just-in-time inventory systems, and green energy pilots aren’t just cool words—they actually show up here first, before spreading across the industry. It's why car quality has gone up, costs have come down, and Indian cars are now showing up on roads not just in India, but in Europe and Africa, too.

Check out these quick stats on the plant’s impact:

| Impact Area | Quick Fact |

|---|---|

| Jobs | 17,000+ direct, up to 85,000 indirect |

| Production | Over 1.6 million cars a year |

| Exports | Cars shipped to 100+ countries |

| Tech Training | 12,000+ apprentices trained since 2007 |

So yeah, the largest car plant India has ever seen isn’t just about shiny new cars. It keeps towns humming, powers Uncle’s auto parts shop, and gives kids in the area a shot at serious technical careers—maybe even nudging a few into launching their own start-ups one day. All this, just from what started out as a big project on Haryana’s map.

Behind the Scenes: Robots, Humans, and Innovations

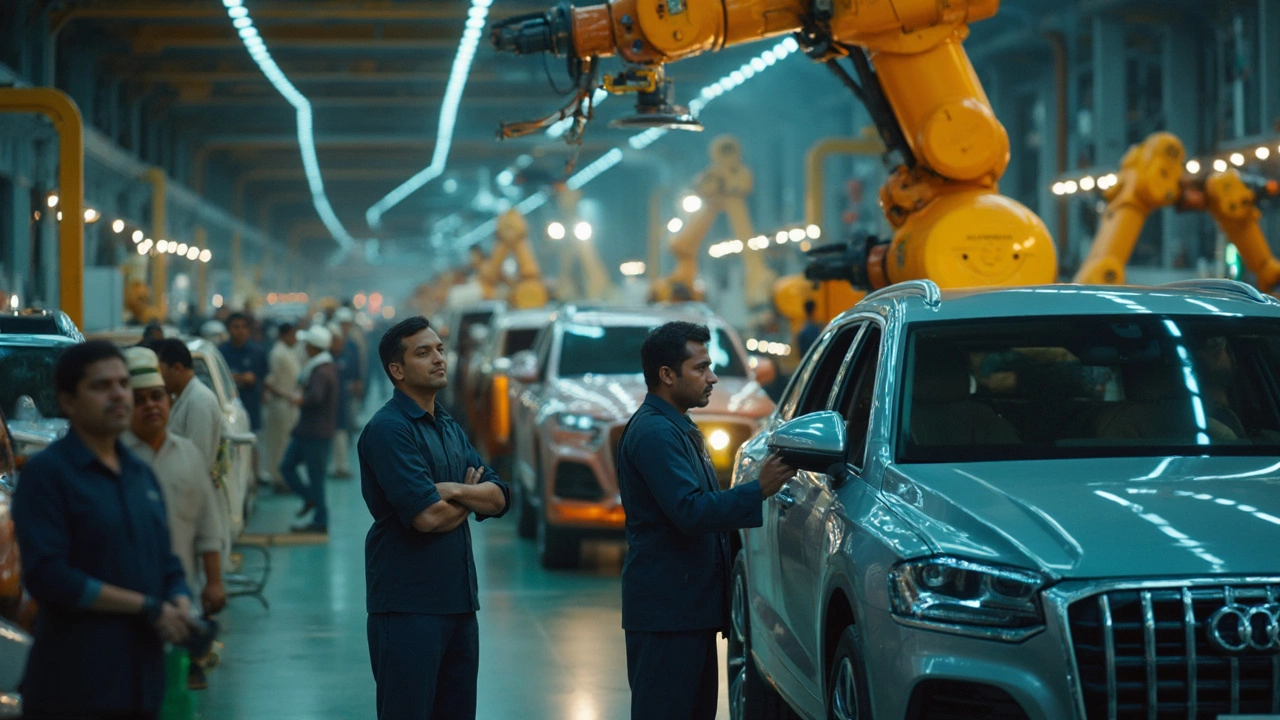

Walking into the Maruti Suzuki Manesar plant feels like stepping onto a futuristic movie set, minus the Hollywood drama. Robots and people work side by side to build cars at a crazy-fast pace, and it’s wild to see how well they coordinate. Each shift brings together more than 10,000 employees, ranging from engineers to line workers and software techs. These aren't just workers—they’re the reason the factory runs like a well-oiled machine.

Robots aren’t just for show here. Over 1,700 robots handle welding, assembly, and even paint jobs. A single robot arm can spot-weld 20 times faster than a person, which helps push out thousands of cars a day. But people still run the show for quality checks, final assembly fitments, and tinkering with those unexpected glitches no machine can handle yet.

The plant has invested heavily in digital tools. Workers use tablets to track every step of car assembly, and AI systems flag issues in real time. This isn’t just for speed—these upgrades help cut down waste and keep mistakes from slipping through. Workers say these changes cut the number of re-dos by nearly 30% since 2020.

Productivity here isn’t just a buzzword. Here’s a quick look at what gives Manesar its edge:

- Automation rate: Nearly 60% of welding is handled by robots.

- Power efficiency: The plant slashed its energy use per car by 12% in the last three years using solar arrays and efficient machines.

- Training programs: Every worker goes through regular micro-training every month—think bite-sized lessons via apps and video, not old-school lectures.

- Rapid prototyping: New models are tested on virtual simulators first, cutting development timelines by months.

You can see the balance between tech and human skill in numbers:

| Factor | Stat (2024) |

|---|---|

| Total Employees | 10,700+ |

| Robots Installed | 1,700+ |

| Cars Produced Daily | 5,800 |

| Energy Saved (MWh/year) | 10,000 |

| Automation (Body Shop) | Nearly 60% |

It’s not just about cranking out numbers. The plant’s mix of robots and humans means faster rollouts, fewer headaches for buyers down the line, and better job security. It’s the beating heart of largest car plant India—where next-gen cars hit the road, powered by both brains and bots.

Tips for Visitors and Industry Watchers

Getting up close with the largest car plant India has to offer isn't as simple as showing up at the gate. Maruti Suzuki's Manesar plant is a high-security workplace, but they do let groups in on scheduled tours. These factory visits are a goldmine for car fans, business students, and anyone itching to see car-building robots in action.

- Book ahead: The plant runs limited tours, mostly for student groups, auto professionals, or partner companies. Regular folks need to email Maruti Suzuki’s official contact well in advance—think two to three months.

- ID is mandatory: You’ll need to bring government photo ID. They are serious about security; no ID, no entry.

- No photos allowed: Leave the camera in your bag. Photography is banned almost everywhere inside, mainly to protect trade secrets.

- Wear comfy shoes: The walking route covers several kilometers—expect to be on your feet a lot, moving from the pressing shop to assembly lines and testing bays.

If you can’t book a visit, the next best thing is checking out the annual Auto Expo in Delhi. Maruti Suzuki always has a huge presence, along with live demos and displays showing off fresh tech from the Manesar plant. It’s a great way to get a sense of their scale and new models brewing.

For those tracking the business side, Manesar’s real draw is its numbers. The plant produces one car almost every 12 seconds when running full tilt. Here’s a quick peek at some visitor-relevant figures from recent years:

| Fact | Detail |

|---|---|

| Annual Output | 1.35 million cars (2024) |

| Full Plant Area | Over 600 acres |

| Number of Employees | More than 15,000 |

| Daily Engine Output | 3,800 engines per day |

| Key Tour Zones | Press Shop, Welding Shop, Assembly, Testing |

Industry watchers should keep an eye on the new digital initiatives. This plant was among the first in India to use AI-controlled robots for quality checks—something that’s changed the way cars are inspected and delivered. If you’re into future trends, follow the company’s press releases for updates on electric vehicle assembly expansions and smart manufacturing projects.