Food Processing Fields Explorer

Explore the different fields of food processing and understand how they work together to transform raw ingredients into safe, market-ready products.

Primary Processing

Raw material preparation

Secondary Processing

Product formulation & cooking

Tertiary Processing

Final product & packaging

Quality Control

Standards & testing

Automation

Efficiency & consistency

Regulatory Compliance

Standards & sustainability

Selected Field Details

Select a field above to see detailed information about that processing stage.

Processing Workflow Example

See how these fields work together in a real-world scenario:

- Primary Processing: Wash, sort, and cut fresh vegetables

- Secondary Processing: Blanch to preserve color and nutrients

- Quality Control: Test for safety and quality standards

- Tertiary Processing: Portion and flash-freeze the product

- Packaging: Seal with label and barcode

- Automation: Monitor temperature and conveyor speeds

- Regulatory Compliance: Verify labeling and safety standards

When you look at the grocery aisle, the variety of products you see-fresh fruit, frozen meals, canned soups, snack bars-are the result of a complex web of activities that turn raw farm produce into safe, tasty, and shelf‑stable foods. Those activities are grouped into distinct food processing fields that each focus on a specific part of the journey from farm to fork.

Key Takeaways

- Food processing splits into primary, secondary, and tertiary stages, each with its own goals and techniques.

- Preservation, packaging, and quality control are cross‑cutting fields that apply across all stages.

- Automation and equipment choices drive efficiency and consistency in modern plants.

- Regulatory compliance and sustainability are integral to every processing decision.

- Understanding these fields helps manufacturers choose the right tools, staff, and certifications for their products.

What is Food Processing?

Food Processing is the set of operations that transform raw agricultural ingredients into food products ready for distribution and consumption. It encompasses cleaning, sorting, cutting, mixing, cooking, preserving, and packaging, all while ensuring safety, quality, and compliance with regulations.

Primary Processing: Turning Raw Materials into Usable Ingredients

Primary processing deals directly with harvested crops, livestock, or seafood. The goal is to make raw goods easier to handle, store, and transport.

- Cleaning & sorting: removes dirt, debris, and off‑spec items.

- Size reduction: grinding wheat into flour or chopping meat into cuts.

- Extraction: pressing olives for oil or juicing oranges.

- Initial preservation: quick‑freezing fish or chilling milk to slow microbial growth.

Equipment like conveyors, sifters, and industrial blenders dominate this field. Automation has introduced sensor‑based sorting that can detect defects faster than human eyes.

Secondary Processing: Adding Value Through Formulation and Cooking

Secondary processing takes primary ingredients and combines, alters, or cooks them into more complex foods.

- Mixing & blending: creating dough, batter, or emulsions.

- Cooking & thermal treatment: baking bread, pasteurizing sauces, or roasting coffee.

- Fermentation: producing yogurt, cheese, and beer.

- Extrusion: shaping snack foods and pasta.

This stage often uses Food Safety protocols such as HACCP (Hazard Analysis Critical Control Points) to identify points where contamination could occur and implement controls.

Tertiary Processing & Packaging: Ready‑to‑Eat Products

Tertiary processing focuses on final product formation, portioning, and packaging for the consumer market.

- Portioning: dividing ice cream into tubs or candy into bars.

- Enrichment & fortification: adding vitamins to breakfast cereals.

- Final cooking or reheating: ready‑to‑heat meals.

- Packaging: sealing, labeling, and applying barcodes.

Packaging is a cross‑cutting field that protects food, extends shelf life, and communicates brand information. Modern packaging blends materials like PET, aluminum, and biodegradable films, often using vacuum or modified atmosphere technologies to keep foods fresh.

Quality Control & Assurance: Keeping Standards High

Across every processing stage, Quality Control ensures that products meet defined specifications for taste, texture, appearance, and safety. Key activities include:

- Sampling and laboratory testing for microbial load, allergens, and nutrient content.

- Instrumental analysis such as texture analyzers, spectrophotometers, and gas chromatography.

- Statistical process control (SPC) charts to monitor process stability.

Quality assurance teams often adopt ISO 22000 or other international standards to harmonize their procedures across multiple facilities.

Automation, Equipment, and Process Engineering

Automation is reshaping all fields of food processing by reducing labor costs and improving repeatability. Common technologies include:

- PLC‑controlled conveyor systems for continuous flow.

- Robotic arms for pick‑and‑place packaging.

- IoT sensors that monitor temperature, humidity, and pressure in real time.

- Digital twins that simulate production lines before physical implementation.

Choosing the right equipment depends on product type, batch size, and desired throughput. For example, a high‑speed rotary oven works well for bakery items, while a batch‑type retort suits canned soups.

Regulatory Compliance & Sustainability

Food processors must navigate a maze of local, national, and international regulations. In Australia, the FSANZ (Food Standards Australia New Zealand) sets standards for additives, labeling, and maximum residue limits.

Sustainability is now a core requirement. Companies are adopting:

- Water‑recycling systems in washing stations.

- Energy‑efficient heat exchangers for pasteurization.

- Packaging made from recycled or compostable materials.

Meeting these expectations not only avoids penalties but also appeals to increasingly eco‑conscious consumers.

Comparison of Major Food Processing Fields

| Field | Primary Goal | Typical Techniques | Key Equipment | Regulatory Focus |

|---|---|---|---|---|

| Primary Processing | Prepare raw material for further use | Cleaning, size reduction, extraction | Conveyors, sifters, industrial grinders | Residue limits, hygiene standards |

| Secondary Processing | Transform ingredients into intermediate products | Mixing, cooking, fermentation, extrusion | Mixers, ovens, fermenters, extruders | HACCP, temperature control |

| Tertiary Processing & Packaging | Finalize product for consumer use | Portioning, fortification, final cook, sealing | Form-fill-seal machines, labeling systems | Labeling, allergen declarations |

| Quality Control | Ensure product meets specs | Sampling, lab testing, SPC | Analyzers, sensors, data software | ISO 22000, audit trails |

| Automation & Equipment | Increase efficiency and consistency | PLC control, robotics, IoT monitoring | Robotic arms, digital twins, SCADA | Data integrity, traceability |

Putting It All Together: A Practical Workflow

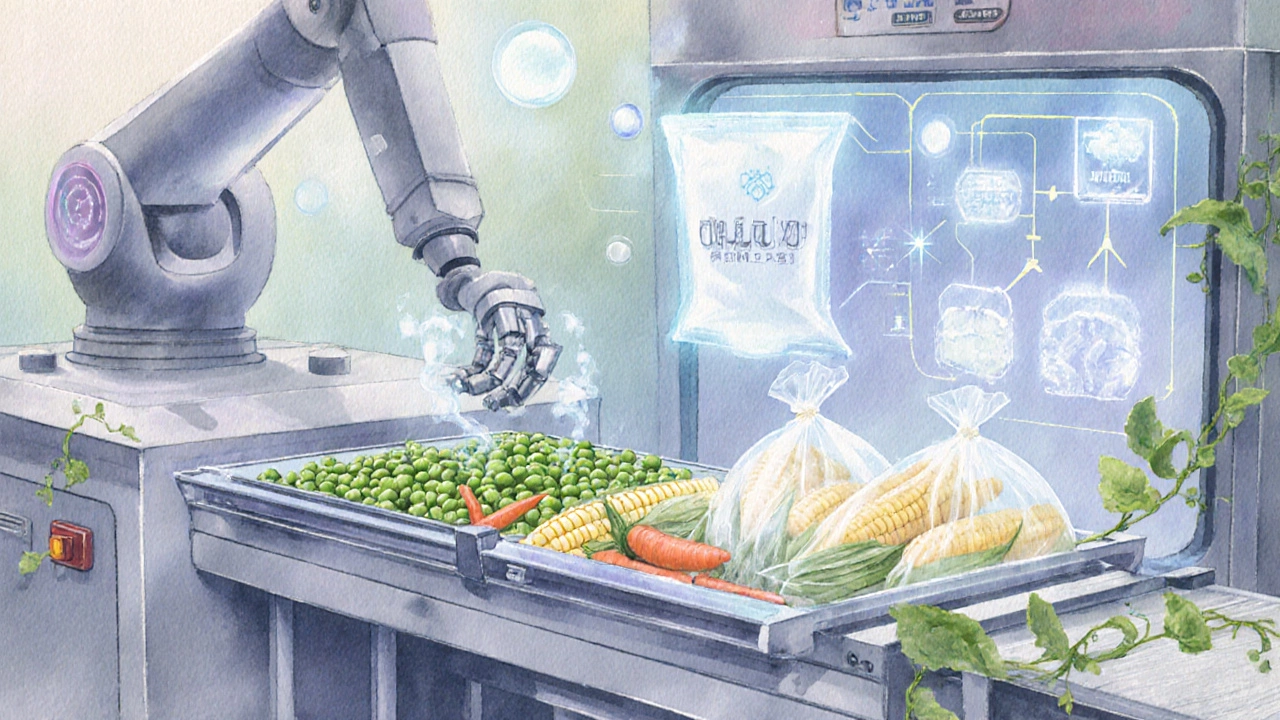

Imagine a company launching a new frozen vegetable blend. The workflow might look like this:

- Primary processing: Fresh peas, carrots, and corn are washed, sorted, and cut.

- Secondary processing: The cuts are blanched to lock in color and nutrients.

- Quality control: A batch sample is tested for microbial load and texture.

- Tertiary processing: The blanched mix is portioned into bags, flash‑frozen, and sealed.

- Packaging: Bags receive a label with nutrition facts, QR code, and best‑by date.

- Automation: PLCs coordinate the conveyor speed, while IoT sensors verify freezer temperature.

- Regulatory check: The final product is verified against FSANZ labeling requirements before shipment.

This end‑to‑end view shows how each field contributes to a safe, market‑ready product.

Frequently Asked Questions

What is the difference between primary and secondary processing?

Primary processing handles raw agricultural produce, focusing on cleaning, size reduction, and initial preservation. Secondary processing takes those cleaned ingredients and mixes, cooks, ferments, or otherwise transforms them into more complex food items.

Why is packaging considered a separate field?

Packaging protects the product from physical damage, contamination, and oxidation, while also providing marketing information. Its material choices and sealing technologies directly affect shelf life and compliance with labeling laws.

How does automation improve food safety?

Automation reduces human contact, minimizes error rates, and enables real‑time monitoring of critical parameters like temperature and humidity. Data logs from PLCs and IoT sensors provide an audit trail that satisfies many regulatory requirements.

What certifications should a food processor aim for?

Key certifications include HACCP for hazard control, ISO 22000 for food safety management, and, depending on the product, organic or gluten‑free certifications. Meeting these standards demonstrates compliance and builds consumer trust.

Can small‑scale producers adopt these fields?

Yes. Even a boutique bakery must consider primary (ingredient sourcing), secondary (mixing and baking), quality control (taste tests), and packaging (labeling). Affordable automation tools like tabletop mixers or low‑cost vacuum sealers make it possible for smaller operations.