Manufacturing Job Impact Calculator

How Manufacturing Creates Jobs

The article states that for every manufacturing job, 1.8 additional jobs are created in supply chains, logistics, and local businesses. Average manufacturing wages are $28.50 per hour (22% higher than average private sector jobs).

Job Impact Analysis

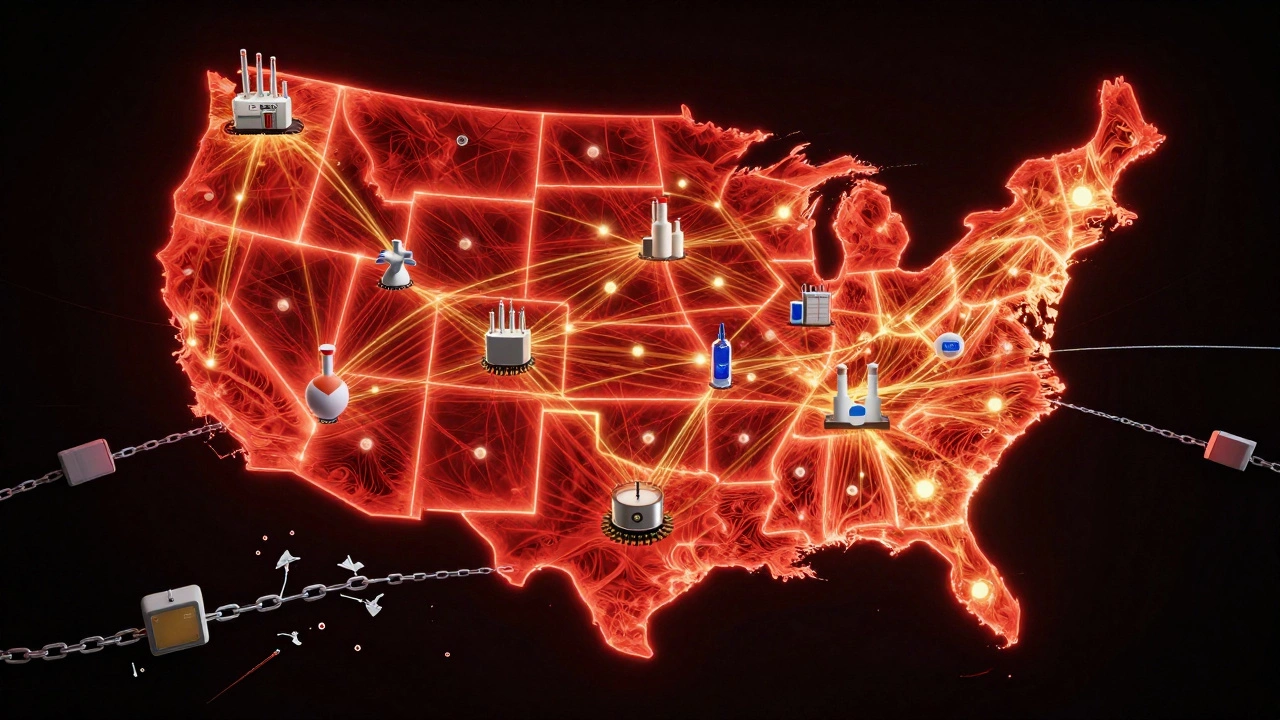

Manufacturing isn’t just about factories and assembly lines-it’s the backbone of America’s economy, its security, and its ability to innovate. While the country has shifted toward services over the last few decades, manufacturing still employs over 13 million people and contributes more than $2.3 trillion to the U.S. GDP each year. It’s not just a sector; it’s the engine that powers everything from smartphones to fighter jets, from insulin to electric vehicles.

Manufacturing Creates Good-Paying Jobs

When you think of manufacturing jobs, you might picture low-wage, repetitive work. But that’s not the reality today. The average manufacturing worker in the U.S. earns $28.50 per hour-22% more than the average private-sector worker. Add in benefits like health insurance and pensions, and the total compensation package jumps even higher.

These aren’t just entry-level jobs. A CNC machinist in Ohio, a robotics technician in Georgia, or a quality control engineer in Michigan often needs specialized training-not always a four-year degree, but definitely a certificate or apprenticeship. Community colleges across the country have partnered with manufacturers to build these pipelines. In Wisconsin, the Advanced Manufacturing Partnership has trained over 12,000 workers since 2020, with 92% of them hired within three months.

Manufacturing jobs also create ripple effects. For every job in a factory, another 1.8 jobs are created in supply chains, logistics, engineering firms, and local businesses. A single auto plant doesn’t just employ 2,000 people-it supports auto parts suppliers, trucking companies, machine tool vendors, and restaurants near the plant.

It Keeps Innovation Alive

Most of America’s breakthrough technologies were born in factories, not labs. The microchip didn’t just appear-it was mass-produced in clean rooms across Texas and Oregon. The lithium-ion battery powering your phone? It was refined and scaled by manufacturers in Nevada and Michigan. Even AI tools like ChatGPT rely on custom silicon chips made in U.S. fabs.

Manufacturing forces innovation to meet real-world constraints. You can design a new drone in a garage, but making 10,000 of them that work reliably, safely, and affordably? That’s where engineering, materials science, and process control come together. That’s why 70% of U.S. corporate R&D spending happens inside manufacturing firms, according to the National Association of Manufacturers.

Take the example of the CHIPS and Science Act passed in 2022. The U.S. government pledged $52 billion to bring semiconductor production back home. Companies like Intel, TSMC, and Micron are building new fabs in Arizona, Ohio, and New York. These aren’t just factories-they’re innovation hubs where engineers, physicists, and technicians work side by side to push the limits of what’s possible.

Manufacturing Strengthens National Security

When the pandemic hit in 2020, America couldn’t make enough masks, ventilators, or test kits. The U.S. had outsourced 90% of its medical supply chain overseas. That wasn’t just inconvenient-it was dangerous.

Today, the Department of Defense spends over $150 billion annually on U.S.-made equipment. Fighter jets, submarines, missile systems, and encrypted communication gear can’t be trusted if they’re built in countries with unstable supply chains or hostile governments. The Pentagon now requires that critical defense components come from American soil. The Defense Production Act has been used more in the last five years than in the previous 30 combined.

Even everyday items matter. Batteries for military drones, rare earth magnets for guidance systems, and high-strength steel for armored vehicles-all require domestic production. China controls 80% of the world’s rare earth processing. The U.S. is now investing in domestic refining plants in Texas and California to break that dependency.

Government Schemes Are Bringing Manufacturing Back

The federal government isn’t just watching-it’s actively rebuilding American manufacturing. The Inflation Reduction Act of 2022 included over $30 billion in tax credits for clean energy manufacturing. Companies that build solar panels, wind turbines, or battery plants in the U.S. get up to 30% of their capital costs back as a tax credit.

States are matching this energy. Texas offers up to $15,000 per new manufacturing job created. Georgia gives companies $10,000 per job for five years if they hire in designated Opportunity Zones. Even small towns are getting in on it: in rural West Virginia, a $50 million state grant helped a local firm start making hydrogen fuel cells.

These aren’t handouts. They’re performance-based incentives. Companies have to meet hiring targets, invest in training, and source materials domestically to qualify. The goal isn’t just to bring back factories-it’s to build better, smarter, more resilient ones.

Manufacturing Reduces Trade Deficits

The U.S. imported $1.1 trillion more in goods than it exported in 2023. That’s a massive hole in the economy. But manufacturing is helping close it.

Since 2021, U.S. exports of manufactured goods have grown by 17%. Machinery, aircraft, pharmaceuticals, and semiconductors are now the top exports. American-made semiconductors alone are worth over $60 billion a year in exports.

Why? Because when you make things at home, you control the quality, cost, and delivery. A U.S.-made medical device doesn’t get stuck in a Shanghai port. A U.S.-built wind turbine doesn’t face tariffs from Europe. That reliability makes American products more attractive globally.

And it’s not just big companies. Small U.S. manufacturers are exporting more than ever. In 2024, over 220,000 small businesses shipped goods overseas-up 35% since 2020. The Small Business Administration now runs export mentoring programs in 48 states.

Manufacturing Builds Stronger Communities

When a factory opens in a town, it doesn’t just bring jobs-it brings stability. Schools get better funding. Local businesses thrive. Crime rates drop. Property values rise.

Take the case of Dayton, Ohio. Once a manufacturing hub that lost over 100,000 industrial jobs between 1980 and 2010, the city saw a turnaround after the state invested in advanced manufacturing training centers. Today, it’s home to over 50 new tech-driven factories, including a 3D printing hub for aerospace parts. Unemployment fell from 8.5% to 3.9% in five years.

These aren’t just economic wins-they’re social ones. Workers who once commuted two hours for a retail job now walk to a factory shift. Their kids see a future in skilled trades. Grandparents see their grandchildren earning a living wage without student debt.

It’s Not Perfect-But It’s Getting Better

Manufacturing still faces challenges: labor shortages, supply chain fragility, and the need for constant tech upgrades. But the tide is turning. In 2024, U.S. manufacturing output hit its highest level ever. New factories are breaking ground every week. And for the first time in 20 years, more young people are choosing manufacturing careers over traditional college paths.

The message is clear: America doesn’t need to choose between services and industry. It needs both. And manufacturing? It’s the foundation that makes everything else possible.

Does manufacturing still matter in the digital age?

Yes, more than ever. Digital tools like AI and robotics are making manufacturing smarter, not obsolete. Every app, every website, every smart device relies on physical hardware made in factories. Without manufacturing, the digital world doesn’t exist.

Why are U.S. factories reopening after closing in the 2000s?

Three reasons: automation lowered labor costs, supply chain disruptions made overseas production risky, and government incentives made domestic production profitable. Factories today use robots to do repetitive tasks, so they need fewer workers-but those workers are better paid and more skilled.

How do government incentives actually work for manufacturers?

They’re not free money. Companies get tax credits, grants, or low-interest loans-but only if they meet strict conditions: hire local workers, invest in training, source materials domestically, and meet environmental standards. For example, the CHIPS Act requires semiconductor firms to keep production in the U.S. for 10 years to keep their funding.

Can the U.S. compete with countries like China in manufacturing?

Not on price alone. China still wins on volume and low-cost labor. But the U.S. wins on quality, speed, innovation, and reliability. American manufacturers produce high-value goods like jet engines, medical devices, and advanced electronics that can’t be easily copied. Customers pay more for products they can trust.

What skills do you need to work in modern manufacturing?

Not just welding or assembly. Today’s factory workers need to read blueprints, program robots, troubleshoot sensors, and use data dashboards. Many jobs require certifications in CNC machining, industrial robotics, or lean manufacturing. Community colleges and trade schools offer 6-month to 2-year programs that lead directly to jobs paying $50,000-$80,000 a year.

What Comes Next?

The next five years will decide whether America reclaims its industrial edge-or lets it slip away again. The key is investing in people: training the next generation of technicians, supporting small manufacturers with access to capital, and keeping supply chains secure.

Manufacturing isn’t about nostalgia. It’s about control. Control over your health, your security, your technology, and your future. And right now, America is choosing to build that future at home.