Food Unit Operations Classifier

Select a category below to explore typical unit operations used in food processing:

Physical

Changes size, shape, phase, or distribution

Chemical

Modifies composition via reactions or mass transfer

Biological

Uses microorganisms or enzymes to transform substrates

Physical Operations

These operations change the physical characteristics of food materials without altering their chemical composition.

Examples: Grinding wheat, centrifuging cream, blending spices

- Material form (solid, liquid, suspension)

- Desired change (temperature, composition)

- Scale & throughput requirements

- Regulatory constraints

- Energy & cost considerations

- Combine operations for complex transformations

- Consider automation for consistency

- Plan for cleaning-in-place (CIP)

- Evaluate sustainability options

- Match equipment to process scale

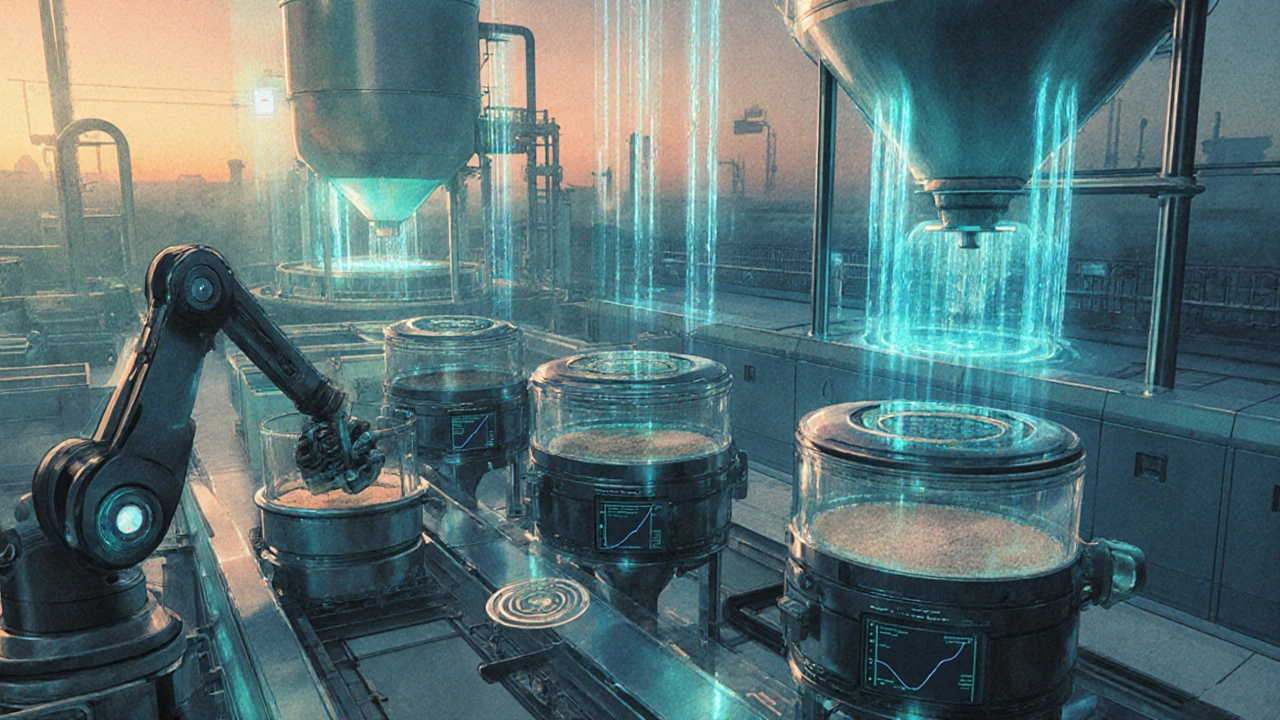

When you walk into a bakery, a dairy plant, or a snack factory, you see finished products, but behind the scenes a set of core actions shape raw ingredients into what ends up on the shelf. Those core actions are called unit operations. Understanding how they’re grouped helps engineers design efficient lines, troubleshoot bottlenecks, and meet safety standards.

What Exactly Is a Unit Operation?

Unit operation is a basic step that changes the physical or chemical state of food material without altering its fundamental composition. It is the building block of any food‑processing plant, whether you’re heating a sauce or separating fat from milk. Think of it as a LEGO brick: combine enough bricks in the right order and you get a complete structure.

Why Classify Unit Operations?

Classification lets engineers quickly pick the right tool for a job, compare alternatives, and communicate with vendors. It also aligns with academic curricula, safety regulations, and industry standards, making training and documentation smoother.

Three Main Classification Groups

Food‑process engineers traditionally split unit operations into three families based on the kind of change they impose on the material.

| Category | Typical Unit Operations | Primary Purpose | Example Applications |

|---|---|---|---|

| Physical | Separation, Size Reduction, Mixing, Drying | Change size, shape, phase, or distribution | Grinding wheat, centrifuging cream, blending spices |

| Chemical | Heat Transfer, Evaporation, Extraction, Reaction | Modify composition via reactions or mass transfer | Pasteurization, solvent extraction of oils, caramelization |

| Biological | Fermentation, Enzymatic Treatment, Bioconversion | Utilize microorganisms or enzymes to transform substrates | Yogurt fermentation, cheese ripening, bread leavening |

Physical Unit Operations

Separation is a process that splits a mixture into its components based on size, density, or solubility. Techniques include filtration, centrifugation, and decanting. For instance, a juice plant uses centrifugal separators to pull pulp from liquid, improving clarity and shelf life.

Size Reduction (grinding, milling, shredding) reduces particle dimensions to increase surface area, enhance extraction, or achieve a desired texture. In a bakery, milling wheat to a fine flour dramatically affects dough elasticity.

Mixing uniformly distributes ingredients to create homogenous intermediates. High‑shear mixers are essential for emulsifying oil and water in dressings.

Drying removes moisture to extend shelf life and reduce weight. Spray‑drying turns liquid milk into powdered form, a staple in emergency rations.

Chemical Unit Operations

Heat Transfer adds or removes thermal energy to achieve sterilization, cooking, or cooling. Pasteurizers use indirect heat exchangers to kill pathogens without compromising flavor.

Evaporation concentrates liquids by boiling off water under reduced pressure, useful for syrup production. Solvent extraction pulls valuable lipids from oilseeds, a step before refining.

Chemical reactions-like the Maillard browning that gives baked crust its color-are controlled in reactors that manage temperature, residence time, and agitation.

Biological Unit Operations

Fermentation leverages microorganisms to convert sugars into acids, gases, or alcohols. Yogurt cultures ferment lactose into lactic acid, thickening the product and adding tang.

Enzymatic treatment uses isolated enzymes to modify proteins, starches, or lipids. For example, proteases break down whey proteins, improving solubility in sports drinks.

Bioconversion can also refer to the use of fungal cultures to produce flavor compounds, such as the smoky notes generated by liquid smoke processes.

How to Choose the Right Unit Operation for Your Process

- Material Form: Is your raw material solid, liquid, or a suspension? Solids often need size reduction before mixing.

- Desired Change: Do you need to change temperature, composition, or both? Heat transfer and chemical reactions may be combined.

- Scale & Throughput: Laboratory‑scale trials may use batch mixers, while industrial lines favor continuous screw conveyors.

- Regulatory Constraints: Dairy products must meet pasteurization standards; sugar‑free beverages may require enzymatic sweetener removal.

- Energy & Cost: Drying is energy‑intensive; consider spray‑drying versus drum‑drying based on utility rates.

Mapping these criteria into a decision tree helps avoid over‑engineering. For example, if you only need to separate cream from milk, a high‑speed centrifuge (physical) is more cost‑effective than a multi‑stage evaporation (chemical).

Emerging Trends Shaping Unit Operations

Automation and real‑time monitoring are turning traditional batch units into smart, adaptive systems. Sensors embedded in mixers now feed viscosity data to a PLC, which automatically adjusts impeller speed.

Sustainability pressures are driving low‑temperature pasteurization (high‑pressure processing) and water‑recycling dryers that capture moisture for reuse.

Finally, plant‑based protein manufacturers are blending physical (grinding), chemical (solvent extraction), and biological (fermentation) operations to mimic meat texture while keeping the process efficient.

Quick Checklist for Process Designers

- Identify the primary classification (physical, chemical, biological) for each step.

- Validate that equipment size matches material flow rates.

- Confirm that temperature/pressure limits meet food‑safety regulations.

- Assess energy consumption; look for heat‑integration opportunities.

- Plan for cleaning‑in‑place (CIP) or sanitation requirements early.

Frequently Asked Questions

What is the difference between a unit operation and a unit process?

A unit operation changes the physical state (e.g., mixing, drying) while a unit process involves a chemical or biological transformation (e.g., fermentation, oxidation). Both are essential, but the distinction helps engineers choose the right equipment.

Can one piece of equipment belong to multiple classifications?

Yes. A high‑shear homogenizer physically breaks droplets (physical) while also generating heat that can trigger chemical reactions (chemical). Context determines the primary classification.

Why is heat transfer considered a chemical unit operation?

Heat transfer often drives chemical changes, such as denaturation of proteins or caramelization of sugars. Although the act of moving heat is physical, its purpose in food processing is usually to induce a chemical transformation.

How do I decide between batch and continuous operation?

Batch is flexible and easier to validate for new products. Continuous offers higher throughput and better energy efficiency, but requires stable raw‑material supply and more complex control systems.

What role does automation play in modern unit operations?

Automation provides real‑time data on temperature, pressure, and flow, allowing dynamic adjustments that improve product consistency, reduce waste, and meet stringent safety standards.