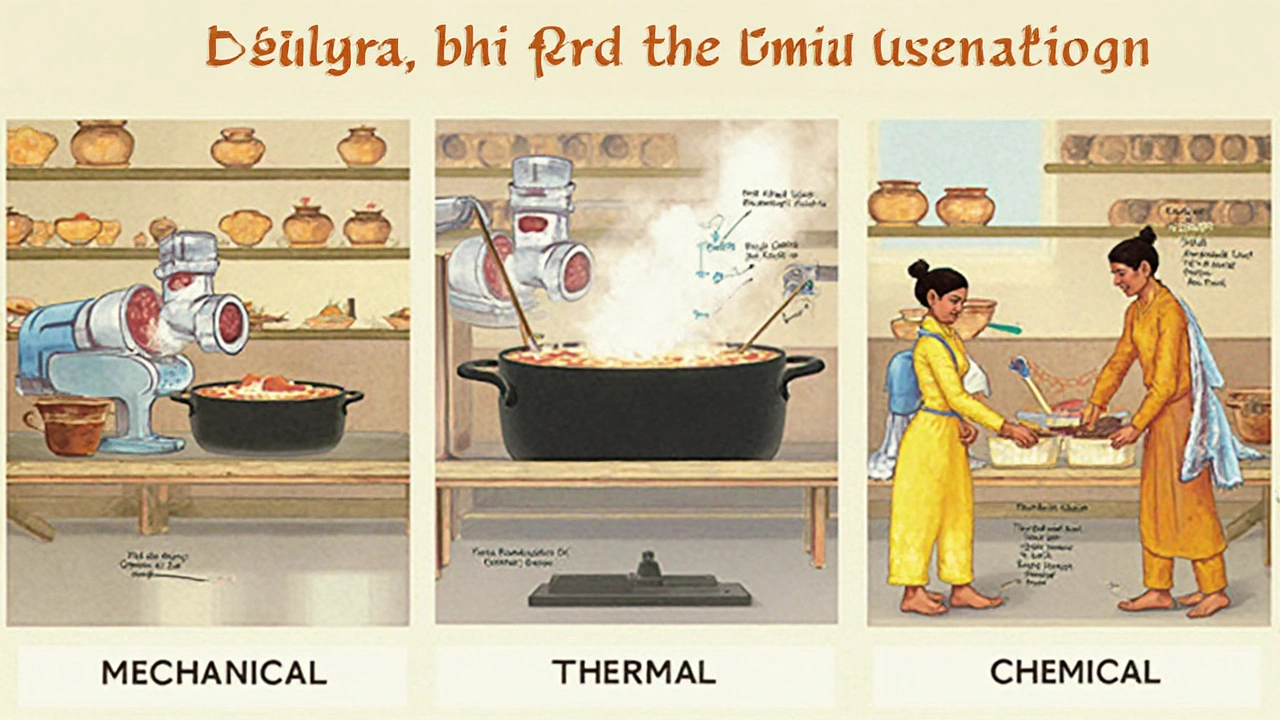

Ever wondered how that delicious snack you love ends up on your table? It’s all about the magic of food processing, and at the heart of it lie unit operations. These are the building blocks that turn raw ingredients into the food products we enjoy every day. Now, let's dig into the different classifications of these operations because understanding them can get you clued up on how your food is made, and yup, it’s actually pretty cool.

Start with mechanical operations—these are all about physical changes in the food. Think chopping, mixing, grinding, or even packaging. Your morning cereal? It got its start in a mechanical unit operation where grains were milled and mixed.

Mechanical Operations

Alright, let's get into the nuts and bolts of mechanical operations in food processing. These are essentially the physical processes that manipulate the size, shape, and texture of food. When you grab a bag of chips at the store, you're looking at the result of some intense mechanical magic.

Food processing units perform these tasks using various equipment. There's milling, which grinds grains into flour or powders; slicing, for your crisp veggies or deli meats; mixing, ensuring everything from cookie dough to salad dressings gets its signature consistency. The goal is to change the food's physical properties to prepare it for the next production stage.

One standout mechanical operation is homogenization. It's not just a fancy word. In the dairy industry, this process breaks down fat globules in milk, giving it that nice uniform texture. Ever notice how milk no longer separates like it used to? Yup, that's homogenization at work.

Plus, we have deaeration, a sneaky but vital process. Imagine a bottle of juice. You definitely don't want air bubbles messing up the flavor or freshness. Deaeration removes those pesky air bubbles, keeping juices tasty and shelf-stable.

To put things into perspective, here's how mechanical operations contribute to different products:

- Grinding: Perfect for spices and grains, ensuring even texture.

- Extrusion: Used to make snacks like pasta, where dough is forced through a mold.

- Filtration: Clarifies liquids by separating out solids. Think clear broths.

The right mechanical operation can revolutionize a product’s quality, shelf life, and overall appeal. And for those in the know in the food industry, these operations aren’t just tasks; they’re strategic moves in creating the next big hit in food processing techniques.

Thermal Operations

Alright, let's get warm with thermal operations—these are all about heat, and they play a huge role in the food processing units. Anytime you're heating, cooling, or any way adjusting the temperature of a food product, you're involved in thermal operations. Why does this matter? Because controlling temperature keeps food safe, gives it a longer shelf life, and makes it tasty.

Think about pasteurization, a process we owe our safe milk and juice to. In pasteurization, the product is heated to a specific temperature to kill harmful bacteria without affecting taste much. Then there's freezing, like the way your frozen veggies retain their nutrients and flavor until you're ready to cook them. It's all thanks to clever thermal operations.

Boiling and blanching are other ways heat is used. Blanching, a quick heat treatment, is often used in food industry to preserve color, flavor, and vitamins while deactivating enzymes that could cause spoilage.

To put it simply, thermal operations are like Mother Nature's clock, working behind the scenes to make sure our food is safe, nutritious, and flavorful. Whether it’s your favorite frozen pizza or that can of soup that’s saved many a dinner, thermal operations make it possible. So next time you’re cozying up with a hot meal or tossing a salad with chilled veggies, take a moment to appreciate the heat (or lack thereof) that’s made it all possible!

Chemical Operations

Diving into the world of food processing units wouldn't be complete without talking about chemical operations. These processes involve chemical changes to the food that often enhance flavor, preservation, or nutritional value. A classic example you might recognize is fermentation. This age-old method is used to produce everything from beer to yogurt, relying on good bacteria to transform ingredients into something delicious and shelf-stable.

Another big player in unit operations is the use of enzymes. Enzymes are like little productivity ninjas. They speed up reactions during food processing which can alter texture, flavor, and even nutritional profiles. Think about the tender meat from enzyme injections or the sweet notes in fruit juices enhanced by enzyme treatments.

Preservation through chemical means is also critical. Chemical preservatives can keep foods fresh by preventing spoilage. Look at brine in pickling or nitrates in cured meats. These chemical operations ensure that our food stays safe and lasts longer.

Here’s an interesting fact: chemical operations aren’t just about adding things. They also involve removing undesirable components. Decaffeination is a good example. Chemical solvents are used to effectively yank out caffeine from coffee beans, giving you that delightful decaf brew.

To wrap it up, chemical operations are like the alchemists of food processing. They transform, preserve, and even improve foods by leveraging chemical reactions, making them vital cogs in the machinery of the food industry.

Innovations and Applications

When it comes to food processing units, innovation is the name of the game. This industry is constantly pushing the envelope to make food production faster, more efficient, and eco-friendly. Let’s take a peek into some of the cool stuff happening today.

One impressive advancement is the use of high-pressure processing (HPP). Unlike traditional methods that rely on heat, HPP utilizes intense pressure to eliminate bacteria without altering taste and texture. So, your favorite juice can stay fresh longer without nasty preservatives, thanks to this thermal alternative.

On the chemical operations front, enzyme technology is gaining traction. By using enzymes, manufacturers can achieve specific transformations in food, like breaking down proteins to improve flavor and texture. This ensures your food isn't just safe but tastier too.

The rise of IoT (Internet of Things) is another game-changer. With smart sensors, factories can monitor everything from humidity levels to machine performance in real-time. This data-driven approach not only boosts efficiency but also slashes waste, a win-win for both producers and Mother Earth.

Check out this table showing some standout stats on where the industry is heading:

| Innovation | Impact |

|---|---|

| High-Pressure Processing | Extends shelf life by up to 50% |

| Enzyme Use | Reduces need for artificial additives by 30% |

| IoT Integration | Improves operational efficiency by 25% |

Then there's the application of robotics in mechanical operations. Robots are now handling repetitive tasks like sorting and packaging, cutting down errors and allowing human workers to focus on more complex jobs. These smart robots aren’t just speeding up processes; they're raising the bar for quality and safety.

All of these innovations are reshaping how food finds its way from farms to your dinner table, making the industry not just more robust, but also ready to tackle future challenges. So, next time you grab a snack, take a moment to appreciate the tech and thought that goes into each bite!